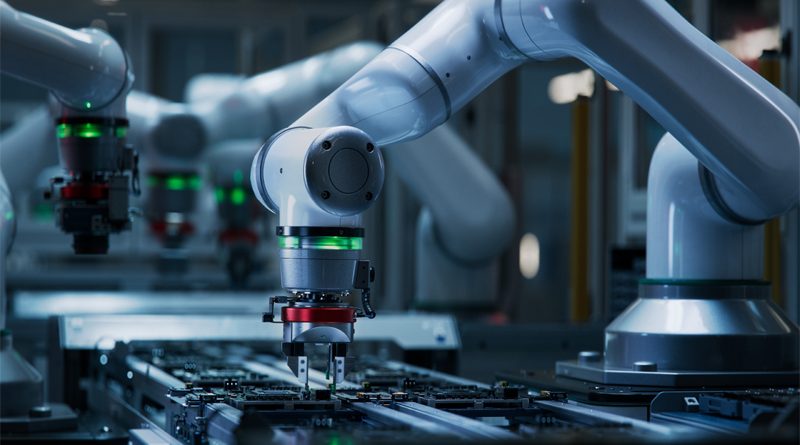

Production robotization – the new norm in modern manufacturing facilities

The trend of robotizing and automating manufacturing processes is accelerating globally. An increasing number of production facilities are investing in advanced machines capable of taking over even hazardous tasks from human workers.

Industrial robots, often operating under challenging conditions, are exposed to detrimental factors such as thermal radiation, hot splatters, moisture, and dust.

As a result, these facilities are now focusing on safeguarding their robots and machinery to prolong their operational life and efficiency.

Prioritizing the prevention of equipment failures and unexpected production halts has gained importance, especially considering the lengthy lead times for ordering new robots and their spare parts.

Choosing the right protection for machinery and equipment – trust in experience

EVOTEC, a Polish company, specializes in creating protective covers for industrial robots and machinery. These covers play a crucial role in helping clients keep their equipment in optimal condition within manufacturing environments.

They shield against heavy dust accumulation, moisture, thermal radiation, and exposure to oils and coolants. EVOTEC’s robot covers are instrumental in enhancing the performance of industrial robots and machinery across global production facilities, ensuring their longevity and reliable operation.

Drawing from years of experience, EVOTEC understands that each manufacturing process is unique, necessitating a bespoke approach.

The company’s objective is to fortify equipment against the most significant threats it faces. To achieve this, every protective cover is custom-made, tailored not just to fit a particular robot model but also to suit its specific application and the operational conditions it encounters.

Tangible benefits of using protective covers include:

- Time efficiency: Significant reduction in production downtimes leads to time savings.

- Enhanced safety and production continuity: By safeguarding vital components and ensuring uninterrupted equipment operation, the covers improve overall safety and maintain steady production flows.

- Increased reliability and operational continuity: The elimination of unexpected downtimes and malfunctions in production lines ensures more reliable and continuous operations.

- Improved aesthetics and cleanliness: Keeping the production area clean contributes to a more orderly and visually appealing workspace.

Innovative design meeting industry standards

EVOTEC’s commitment to innovation is evident in their approach to designing these protective covers. Each product is a result of extensive research and collaboration with industry experts, ensuring not only a perfect fit but also adherence to the highest industry standards.

These covers are not just protective elements; they are a testament to EVOTEC’s dedication to enhancing the efficiency and lifespan of industrial machinery.

The company’s focus on using durable, high-quality materials means that each cover is not only robust against physical and environmental threats but also contributes to the overall sustainability of the manufacturing process.

By reducing the need for frequent equipment maintenance and replacement, EVOTEC’s solutions are an investment in the future of industrial production, making them an essential component for any forward-thinking manufacturing facility.